Fire Protection Services

American Fire Protection Systems, Inc. is equipped to handle all phases of fire protection- engineering and design, project management, installation, repair and maintenance.

Fire Sprinkler System - Engineering and Design

Every project begins with a thorough on-site evaluation of existing facilities. In case of new construction, a blueprint analysis of the fire sprinkler system is carried out. In order to be compliant with the current codes and with insurance requirements, our fire sprinkler contractors and design specialists work closely with government agencies and with insurance companies. While our primary objective is protection, we also work towards reductions in insurance costs. We work keeping in mind budget requirements and also special environmental and material concerns.

Once we have the design in mind, we determine the best system configuration for your project. We have a state- of- the- art CAD team that enables us to expedite processes and helps us meet deadlines. Because we are compatible with the CAD building systems of architects and engineers, we utilize existing construction data and prepare the integrated, comprehensive and consistent design of American Fire Protection System.

Fire Sprinkler Inspections

Ensuring the integrity of the system helps reduce insurance premiums. Fire Sprinkler systems-both new and old, need to be inspected to ensure that they are compliant with fire codes, insurance requirements and client needs. This ensures optimum response time and also ensures accurate operation of sprinkler heads and alarm systems.

Fire Sprinkler Installation

Our team of AFPS’s certified field technicians specializes in providing swift and efficient installation of your Fire Sprinkler system. We ensure that we test each system carefully so that all concerned parties (you and your insurance agency) are satisfied. In order to minimize disruptions to your business activities, we ensure that we pre-assemble, in case of retrofitting.

Riser

It’s is mandatory to be serviced every five years - Annually and Quarterly.

Once in 5 Years, we perform a complete system inspection including water flow of the main drain and back flush of the Fire Department connection.

Annually we provide a visual inspection of the fire sprinkler system, provide Main Drain flow testing and we test the alarm devices for tamper and water flow. Quarterly we provide a visual inspection of the sprinkler system (including heads, gauges, valves, rooms and components).

CERTIFICATION: There is a tag affixed to the riser on Five year and Annual inspection. Paperwork is provided to all customers at all services.

Fire Pumps

Fire Pumps are required to be serviced annually.

During the annual servicing, we carry out a full flow test out of test headers to ensure minimum flow. We use both Diesel and Electric pumps. Fire pumps are stationary pumps that turn on when the fire sprinkler system pressure falls below a minimum threshold. These pumps help the sprinkler system flow at the rated minimums. CERTIFICATION - There is a tag affixed to the pump. Paperwork is provided to all customers at all services.

Fire Hoses

Fire HosesIt is mandatory for fire hoses to be serviced every Five Years, Annually and Semi-Annually.

Five Year Service: We flow test the fire hose, re-rack the hose and conduct hydrostatic testing of the hose.

Annually: We inspect the components of the installed fire sprinkler system, we crack open the valve and repack.

Semi-Annually: We inspect the hose, the valve and the other components.

CERTIFICATION: There is a tag affixed to the hose. Paperwork is provided to all customers at all services.

Standpipes

Fire SprinklerFire Sprinkler are required to be serviced Every 5 Years, Annually, and Semi-Annually;

5 Years: It is mandatory to conduct Flow Tests and Water Pressure Tests to ensure that there are no leaks throughout the fire sprinkler system and that there are no blocks. We ensure that adequate flow is met.

Annually: We provide visual inspection of the valve and the crack valve to ensure ease of valve open and closing.

Semi-Annually: We provide visual inspection to ensure the valve has signed and that there are no obstructions.

Standpipe types: We use Dry, Wet or Combo Dry Standpipe: No Water is used in the system. Fire sprinkler pipes run through the stairwells and buildings all the way to the roof. These are provided with outlets so that the Fire Department can connect to fire hydrant so that while inside, fire fighters can hook up their hoses on each floor or area and fight the fire

Wet Standpipes: The Fire department can connect to fire sprinkler system and pump up with additional pressure so that fire fighters on each level can connect hoses to attack the fire.

Combination Standpipes: Have both dry outlets and Wet.

CERTIFICATION : There is a tag affixed to the standpipes and paperwork is provided to all customers at all services.

Post Indicator Valve - P.I.V.

Post Indicator ValveThese are Control Valves that enable the fire sprinkler system to be turned on or off for testing and they have viewable sites that show the status of the installed Fire Sprinkler system. Break-away locks need to be on the wrench in order to protect against theft or tampering.

Operation Stem & Yoke-O.S.&.Y

Fire SprinklerControl Valve to Fire Sprinkler System. These need to be locked with a chain when not being serviced.

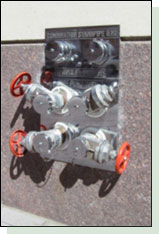

Fire Department Connection-F.D.C.

Fire SprinklerIt needs to be back flushed every 5 years. This is where the fire department connects in order to put additional water and pressure to pump up a fire sprinkler system during a fire to increase water and its keeps fire sprinklers activating at full potential when multiple heads are fused.

Fire Sprinklers in Los Angeles

There are many different types of fire sprinkler heads. Above you see glass bulb style sprinklers. Most Common Colors of Sprinklers: Chrome, Brass, White

Most Common Styles: Pendent (facing down) Upright (facing up) Sidewall (sideways) Dry Pendant (dry sprinklers for freezers and coolers).

Fire Sprinkler Contractor

Above is a concealed sprinkler head. All you see is the white disc.

This is what happens when a sprinkler operates:

Fire Sprinkler Contractor

- Heat from the fire causes the glass bulb to break.

- This releases the cap.

- Water is released onto the diffuser.

- Water puts out the fire.